The Importance and Benefits of Quality in Laser Cutting Services

In the world of manufacturing, precision and reliability are paramount. Laser cutting technology has revolutionized the industry by offering unparalleled accuracy and efficiency. However, the true value of laser cutting services lies in their quality. High-quality laser cutting ensures precision, clean edges, material integrity, and consistency, which are crucial for successful project outcomes. At Mia Makina Demir Çelik San. ve Tic. Ltd. Şti., we leverage advanced laser cutting technology and expert craftsmanship to deliver superior results. Discover the importance and benefits of choosing quality laser cutting services for your business, and how it can enhance your production process while ensuring sustainability and cost efficiency.

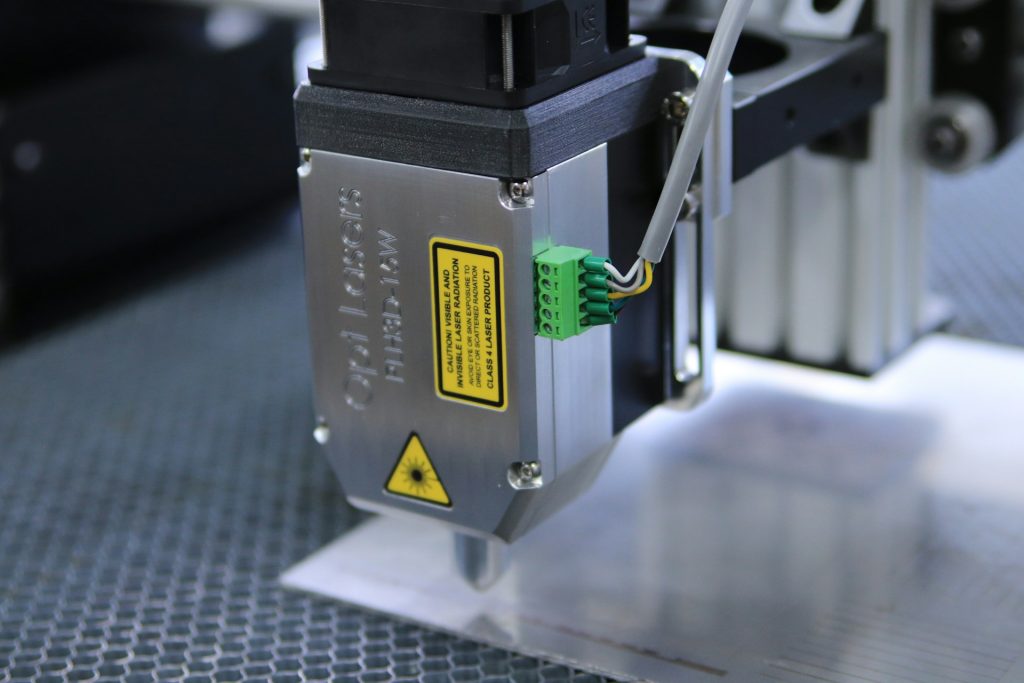

Fundamentals of Laser Cutting Technology

Laser cutting technology is a precise and efficient method used in various industries to cut materials with high accuracy. This process involves directing a high-powered laser beam at the material, which melts, burns, or vaporizes it, resulting in a clean cut. The laser cutting machine follows a pre-programmed design to ensure each cut is exact, making it ideal for intricate designs and detailed work.

The Role and Historical Development of Laser Cutting in Industrial Production

The role of laser cutting in industrial production has been transformative, offering unparalleled precision and efficiency. Initially developed in the 1960s, laser cutting technology has evolved significantly, becoming a staple in modern manufacturing processes. Its ability to produce high-quality cuts with minimal waste has made it indispensable in various industries, from automotive to aerospace. The continuous advancements in laser cutting technology have enhanced its capabilities, making it a cornerstone of sustainable production and cost-efficient manufacturing.

Defining Quality in Laser Cutting

When choosing quality laser cutting services, several key characteristics define a high-standard process. These include:

• Precision: The ability to produce exact cuts that match the specified dimensions.

• Clean Edges: Cuts that are free from burrs and require minimal post-processing.

• Material Integrity: Maintaining the structural properties of the material without causing thermal damage.

• Consistency: Ensuring each cut is identical, crucial for large-scale production.

Measuring Quality in Laser Cutting: Cutting Precision and Surface Quality

How to ensure surface quality in laser cutting is essential for achieving the best results. Measuring quality involves assessing:

• Cutting Precision: This is evaluated by the accuracy of the cut dimensions compared to the design specifications. High precision is critical for parts that need to fit together perfectly.

• Surface Quality: The smoothness and finish of the cut surface are inspected to ensure minimal roughness and absence of defects. High surface quality reduces the need for additional finishing work and enhances the overall appearance and functionality of the final product.

By focusing on these aspects, Mia Makina ensures that every laser cutting project meets the highest standards of quality.

The Impact of High Precision on Product Quality

Cutting precision is a crucial factor in ensuring the overall quality of the final product. High precision in laser cutting technology results in components that fit together seamlessly, reducing the likelihood of errors during assembly. This level of accuracy not only enhances the structural integrity of the product but also improves its aesthetic appeal. By maintaining strict tolerances, high precision ensures that each part performs its intended function effectively, leading to superior product quality and reliability.

The Role of Precise Cuts in Design Freedom and Detailing

Precise cuts are essential for achieving intricate designs and detailed work, offering greater design freedom. This is particularly important for industries where customization and complex geometries are required. With advanced laser cutting technology, manufacturers can create detailed patterns and intricate shapes that were previously impossible with traditional cutting methods. This capability allows designers and engineers to innovate and push the boundaries of what is possible, ultimately leading to more sophisticated and high-quality products.

Surface Quality and Processing Speed

For businesses seeking laser cutting services, prioritizing surface quality and processing speed can lead to significant improvements in production efficiency and overall product quality.

Ensuring Surface Quality in Laser Cutting

Ensuring surface quality in laser cutting is vital for achieving optimal results. High-quality laser cutting services focus on producing smooth, clean edges that require minimal post-processing. This involves using advanced laser cutting technology that precisely controls the laser beam’s intensity, focus, and movement. By maintaining the correct parameters, we prevent material distortion and achieve a high-quality finish. Regular maintenance and calibration of the equipment also play a significant role in maintaining surface quality, ensuring that each cut meets the desired specifications.

Increasing Processing Speed and Efficiency in Production

Increasing processing speed and efficiency in production is a key advantage of using advanced laser cutting technology. Faster processing speeds translate to higher throughput, allowing for more products to be manufactured in a shorter time frame. This efficiency does not compromise quality; rather, it enhances it by reducing lead times and streamlining the production process. Additionally, efficient laser cutting reduces material waste and lowers production costs, making it a cost-effective solution for large-scale manufacturing. By leveraging state-of-the-art laser cutting machines, Mia Makina ensures that your production runs are both fast and efficient, without sacrificing the quality of the final product.

Advantages of Laser Cutting Services

One of the standout advantages of laser cutting services is their flexibility in handling various production scales. Whether you need a single prototype or a full-scale mass production run, laser cutting technology offers unmatched precision and efficiency. For prototypes, laser cutting provides the ability to quickly iterate and refine designs with minimal lead time. When it comes to mass production, the same technology ensures consistent, high-quality cuts across thousands of units, maintaining tight tolerances and reducing the likelihood of errors. This versatility makes laser cutting an ideal choice for businesses looking to streamline their production processes and bring products to market faster.

Material Diversity: Effective Cutting Capability on Different Materials

Laser cutting technology is highly versatile in its ability to cut a wide range of materials with precision and efficiency. From metals like steel and aluminum to non-metals such as plastics, wood, and even textiles, laser cutting services can handle diverse material types with ease. This material diversity allows manufacturers to use the same cutting technology across different projects, enhancing operational flexibility and reducing the need for multiple cutting methods. Effective cutting capability on different materials also means that complex and intricate designs can be achieved without compromising on quality, regardless of the material used. By offering such adaptability, Mia Makina’s laser cutting services cater to a broad spectrum of industrial needs, ensuring precise and high-quality results for every project.

Environmental Impacts and Sustainability

Laser cutting technology stands out as an environmentally friendly production method, offering several green benefits. One of the primary advantages is its ability to produce precise cuts with minimal waste. Unlike traditional cutting methods that often result in significant scrap material, laser cutting maximizes the use of raw materials by producing exact cuts according to the design specifications. This precision reduces the amount of material that ends up as waste, contributing to more sustainable manufacturing practices.

Moreover, laser cutting generates less noise and pollutants compared to other cutting technologies, making it a cleaner alternative for industrial production. The non-contact nature of the process also minimizes the need for harmful lubricants and coolants, which can have adverse environmental effects.

Reduction of Waste Material and Optimization of Energy Usage

One of the key benefits of laser cutting technology is its ability to significantly reduce waste material. The precision of laser cutting ensures that only the necessary material is removed, leading to optimal material utilization. This reduction in waste not only lowers material costs but also minimizes the environmental impact associated with material disposal.

In addition to reducing waste, laser cutting technology optimizes energy usage. Modern laser cutting machines are designed to be energy-efficient, consuming less power while maintaining high levels of performance. This efficiency helps to lower the overall carbon footprint of the production process. By utilizing advanced laser cutting technology, Mia Makina ensures that your projects are not only of the highest quality but also produced in an environmentally responsible manner.

Choosing quality laser cutting services that prioritize sustainability can help businesses achieve their environmental goals while maintaining production efficiency and cost-effectiveness.

Cost Efficiency and Economic Benefits

The cost efficiency of laser cutting is one of its most significant economic benefits. This technology reduces labor costs by automating much of the cutting process, requiring less manual intervention and oversight. Advanced laser cutting machines can operate continuously with minimal supervision, allowing for faster production times and reducing the need for extensive labor.

In addition to labor savings, laser cutting also optimizes material usage, resulting in substantial material savings. The precision of laser cutting ensures that parts are cut accurately, minimizing waste and maximizing the use of raw materials. This efficiency translates to lower material costs and reduces the financial impact of excess scrap.

Optimization of Production Costs and Achieving a Competitive Advantage

Optimization of production costs is a crucial factor in maintaining a competitive edge in the manufacturing industry. Laser cutting technology enables businesses to streamline their production processes, resulting in lower operational costs. By minimizing waste, reducing labor requirements, and speeding up production times, laser cutting helps companies produce high-quality products at a lower cost.

Moreover, the ability to quickly transition from prototype production to mass production without significant changes in setup or tooling provides additional economic benefits. This flexibility allows businesses to respond swiftly to market demands and changes, ensuring they remain competitive.

The combination of reduced labor and material costs, along with enhanced production efficiency, gives businesses a significant competitive advantage. By leveraging the cost efficiency of laser cutting, companies can offer their products at more competitive prices while maintaining high quality, thereby improving their market position and profitability.

The Future of Laser Cutting Technology

The future of laser cutting technology promises exciting innovations and advancements that will further enhance its capabilities and efficiency. One expected development is the improvement of laser sources, such as fiber lasers, which offer higher power and greater precision. These advancements will enable faster cutting speeds and the ability to cut thicker and more diverse materials with even greater accuracy.

Another anticipated innovation is the integration of advanced materials processing techniques, such as ultrafast lasers, which can cut materials at the microscopic level. This will open new possibilities for industries requiring extremely fine and detailed cuts, such as the medical device and microelectronics sectors.

Additionally, the adoption of more sophisticated software and control systems will enhance the automation and precision of laser cutting processes. These systems will allow for more complex geometries and patterns to be cut with minimal human intervention, increasing efficiency and reducing the potential for errors.

The Effects of Digitalization and Automation in the Industry on Laser Cutting

The effects of digitalization and automation in the industry are profoundly transforming laser cutting technology. Digitalization facilitates the seamless integration of laser cutting systems with other digital tools, such as CAD/CAM software, enabling more efficient design-to-production workflows. This integration allows for the quick conversion of digital designs into physical products, significantly reducing lead times and enhancing flexibility.

Automation plays a crucial role in optimizing laser cutting processes, from material handling to quality control. Automated systems can manage entire production lines, ensuring consistent quality and high throughput. Robotics and automated guided vehicles (AGVs) are increasingly used to transport materials to and from laser cutting machines, further streamlining operations and reducing labor costs.

Moreover, the implementation of Industry 4.0 principles, such as the Internet of Things (IoT) and artificial intelligence (AI), is revolutionizing laser cutting technology. IoT-enabled laser cutters can communicate with other machines and systems, enabling real-time monitoring and predictive maintenance. This connectivity helps to minimize downtime and maximize productivity.

AI enhances laser cutting by optimizing cutting paths, adjusting parameters in real-time for optimal performance, and predicting potential issues before they occur. These capabilities lead to higher precision, reduced waste, and increased overall efficiency.

As digitalization and automation continue to advance, the future of laser cutting technology looks increasingly promising. These innovations will not only enhance the quality and efficiency of laser cutting but also expand its applications across various industries, paving the way for more innovative and sustainable manufacturing solutions.

Conclusion: The Competitive Advantage Provided by Quality Laser Cutting Services

In conclusion, quality laser cutting services offer a significant competitive advantage for businesses across various industries. By ensuring precision, consistency, and superior surface quality, laser cutting technology enhances product performance and aesthetic appeal. This high level of quality is critical for achieving customer satisfaction and maintaining a strong market position.

One of the standout benefits of laser cutting is its cost efficiency. The technology reduces labor and material costs through automation and precise material usage. This optimization of production costs allows businesses to offer competitive pricing while maintaining high standards of quality.

Furthermore, the environmental advantages of laser cutting cannot be overlooked. The technology minimizes waste and reduces energy consumption, making it a more sustainable production method. This eco-friendly approach not only helps in reducing the carbon footprint but also aligns with the growing demand for sustainable manufacturing practices.

Looking ahead, the future of laser cutting technology is poised for exciting innovations and advancements. Developments in laser sources, automation, digitalization, and AI integration will continue to enhance the capabilities and efficiency of laser cutting processes. These advancements will enable businesses to produce more complex and high-quality products at faster rates and lower costs.

By leveraging the latest in laser cutting technology and focusing on quality, Mia Makina Demir Çelik San. ve Tic. Ltd. Şti. is committed to providing top-notch laser cutting services that deliver both economic and environmental benefits. Partnering with us means gaining access to state-of-the-art technology and expertise that can drive your business forward, ensuring you stay ahead in a competitive market.