Everything You Need to Know About CNC Milling

CNC milling, a cornerstone of modern manufacturing, enables the precise and complex machining of materials using computer-controlled machinery. This advanced technology ensures high accuracy and repeatability, making it indispensable for various industries. At Mia Makina Demir Çelik San. ve Tic. Ltd. Şti., we have been a leading CNC milling manufacturer and supplier since 2009, providing top-tier CNC milling solutions from our state-of-the-art facilities in Torbalı and Bornova Doğanlar.

In this comprehensive guide, we will cover everything you need to know about CNC milling, including insights into finding reliable CNC milling suppliers, obtaining accurate CNC milling quotes, understanding the import process, and the benefits of working with a trusted CNC milling producer and subcontractor. Discover how Mia Makina excels in delivering superior CNC milling services and why we are the preferred choice for many in the industry.

What is CNC Milling?

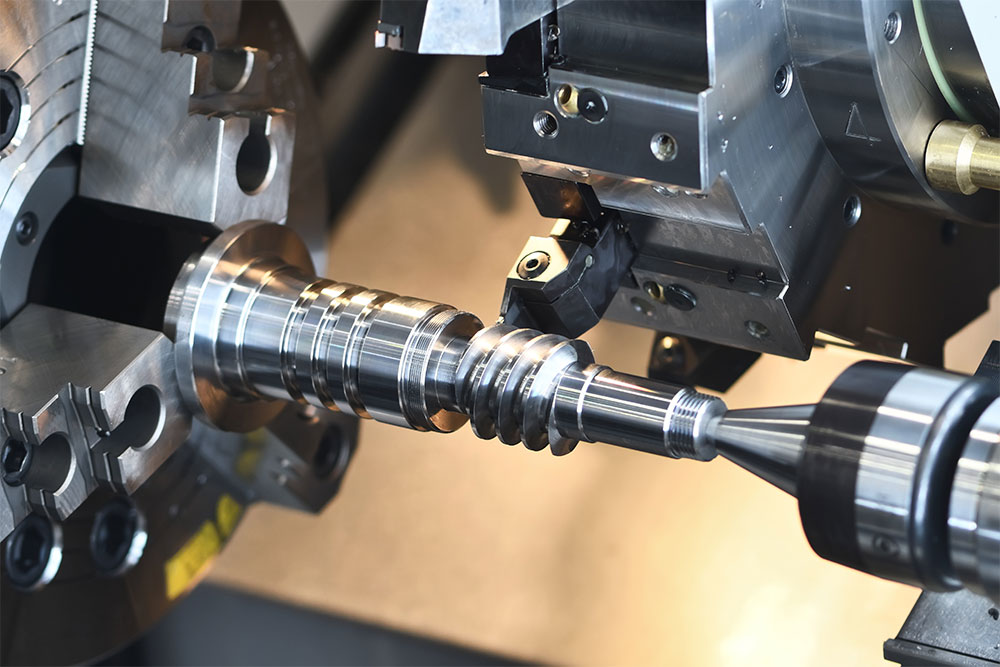

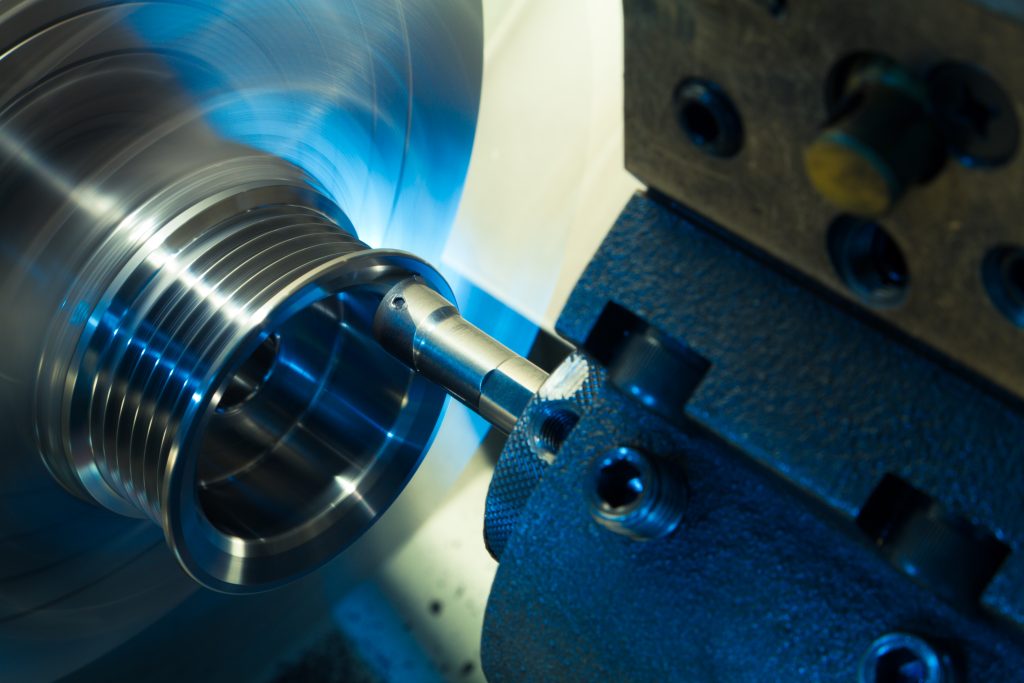

CNC (Computer Numerical Control) milling is a precision machining process that utilizes computer-controlled machines to remove material from a workpiece to create the desired shape and features. Unlike traditional manual milling, CNC milling automates the control of the machine tools, ensuring high precision, repeatability, and efficiency.

Explain the basic concept of milling and how it differs from other machining processes.

The basic concept of milling involves using rotary cutters to remove material from the workpiece. The process can produce a variety of shapes, slots, holes, and contours, making it incredibly versatile. CNC milling differs from other machining processes like turning, where the workpiece rotates, whereas in milling, the cutting tool rotates and moves along multiple axes to achieve the desired shape.

Mention the materials commonly used in CNC milling (e.g., metals, plastics).

Common materials used in CNC milling include metals such as aluminum, steel, and titanium, as well as plastics like ABS, polycarbonate, and nylon. As a leading CNC milling manufacturer, Mia Makina ensures the highest quality machining services for these materials, meeting diverse industry needs with precision and efficiency.

How Does a CNC Machine Work?

The operation of a CNC machine involves a series of steps that transform a digital design into a physical object with high precision. Here’s a detailed overview of the process:

General Operation of a CNC Machine

A CNC machine operates by following programmed instructions to precisely control the movement of cutting tools along various axes. These instructions are generated from a digital design, ensuring that the final product matches the exact specifications. The machine consists of several key components, including the computer control unit, the spindle, the cutting tools, and the worktable.

Steps from CAD to CAM Software

- Design with CAD (Computer-Aided Design): The process begins with creating a digital design of the part or component using CAD software. This software allows engineers and designers to create detailed 2D or 3D models with precise dimensions and specifications.

- Generate Toolpaths with CAM (Computer-Aided Manufacturing): Once the design is complete, it is imported into CAM software. The CAM software translates the CAD model into toolpaths, which are the exact movements the CNC machine’s cutting tools will follow. This includes defining the cutting sequence, speeds, feeds, and depths of cut.

- Convert Toolpaths to G-Code: The CAM software generates a G-Code file, which is a series of instructions written in a language that CNC machines can understand. G-Code dictates every movement of the CNC machine, including tool changes, axis movements, and cutting actions.

Executing Programmed Instructions

- Load the G-Code into the CNC Machine: The G-Code file is transferred to the CNC machine’s control unit. Operators set up the machine by securing the workpiece on the worktable and selecting the appropriate cutting tools.

- Machine Setup and Calibration: The CNC machine is calibrated to ensure accurate positioning. This involves setting the zero points and aligning the cutting tools with the workpiece.

- Execute the Program: Once everything is set up, the CNC machine follows the G-Code instructions to execute the machining process. The machine moves the cutting tools precisely along the defined paths, removing material from the workpiece to create the final part.

- Monitor and Adjust: Throughout the machining process, operators monitor the machine’s performance and make necessary adjustments to ensure quality and accuracy.

Types of CNC Milling

CNC milling encompasses various methods, each suited for specific applications and offering unique benefits. Understanding the different types of CNC milling is crucial for selecting the right approach for your project. Here, we explore the primary methods of CNC milling and their importance in different contexts.

Vertical Milling

Vertical milling involves the use of a vertically oriented spindle that moves up and down while the workpiece remains stationary on the worktable. This method is highly versatile and ideal for creating detailed cuts, holes, and slots in the workpiece. Vertical milling is commonly used for:

- Creating intricate components

- Precision drilling and boring

- Machining flat surfaces

Horizontal Milling

In horizontal milling, the spindle is horizontally oriented, allowing the cutting tools to move horizontally across the workpiece. This method is particularly effective for removing large amounts of material quickly and is often used for:

- Heavy-duty cutting operations

- Machining large, flat surfaces

- Cutting slots and grooves

Importance of Choosing the Right Milling Type

Selecting the appropriate type of CNC milling is vital for achieving optimal results in your specific application. Factors to consider include:

- Complexity of the Part: More complex geometries may require 4-axis or 5-axis milling for precise and efficient production.

- Material Removal Requirements: Horizontal milling is more suitable for heavy material removal, while vertical milling is better for detailed work.

- Production Volume: The chosen milling method should align with your production needs, whether it’s for small-batch or high-volume manufacturing.

- Surface Finish: Different milling types offer varying levels of surface finish quality, impacting the final appearance and performance of the part.

Types of a Milling Machine

Milling machines are essential tools in manufacturing and machining processes, each designed for specific tasks and applications. Selecting the appropriate type of milling machine is crucial for achieving optimal results in terms of efficiency, precision, and production quality. Here, we introduce the different types of milling machines and discuss their importance in various machining tasks.

Ram-type

Ram-type milling machines are characterized by their movable ram that can slide back and forth. This feature allows the cutting tool to reach different areas of the workpiece without moving the entire machine. The ram is mounted on a saddle that moves along the y-axis, while the table can move along the x and z axes.

Common uses of ram-type milling machines include heavy-duty milling operations and large-scale machining tasks where flexibility and reach are essential. They are often used in industrial settings for machining large components.

Knee-type

Knee-type milling machines are one of the most common types, featuring a vertically adjustable worktable that rests on a saddle supported by a knee. The knee can be adjusted vertically to move the workpiece closer to or further from the cutting tool. The spindle can be oriented either vertically or horizontally.

These machines are typically used for general-purpose milling operations such as slotting, drilling, and cutting. They are highly versatile and are often found in tool rooms, job shops, and repair workshops.

Benefits of knee-type milling machines include their flexibility and ease of use for a wide range of milling tasks. However, they may have limitations in handling very large or heavy workpieces compared to other types.

Planner-type

Planner-type milling machines, also known as plano-millers, are designed for heavy-duty machining tasks. These machines have a fixed bed with a movable worktable that moves longitudinally along the bed. The cutting head can move across the table, allowing for extensive and precise cuts on large workpieces.

The primary advantages of planner-type milling machines include their capability to handle large workpieces and perform heavy-duty cutting operations. However, they are typically larger, more expensive, and require more space and maintenance than other milling machines.

Bed-type

Bed-type milling machines have a fixed worktable on which the workpiece is mounted. The cutting head moves along the x, y, and z axes to perform the milling operations. Unlike knee-type machines, the bed-type design offers greater stability and rigidity, making them suitable for heavy and high-precision work.

Features of bed-type milling machines include their robust construction and ability to handle heavy workpieces with high precision. They are commonly used in industries where precision and stability are critical, such as automotive, aerospace, and metalworking.

What Are the Steps of the CNC Milling Process?

CNC milling is a precise and automated process that transforms digital designs into physical components. Each step is crucial for ensuring high-quality results. Here’s a brief overview:

Design and Preparation

The process starts with creating a detailed 2D or 3D model using CAD software, selecting the appropriate material (metals or plastics), and choosing the right cutting tools.

Programming

The CAD design is imported into CAM software to generate toolpaths. This is converted into G-Code, which the CNC machine uses to execute the machining operations.

Setup and Calibration

Operators transfer the G-Code to the CNC machine, secure the workpiece, and select the cutting tools. The machine is then calibrated to ensure accurate positioning and movements.

Machining

The CNC machine executes the G-Code, removing material from the workpiece to create the final shape. Operators monitor the process and make adjustments as needed.

Finishing and Inspection

Post-machining, finishing operations like deburring and polishing are performed. The final part undergoes a thorough inspection to ensure it meets all specifications and quality standards.

Making a CAD Model

Creating a CAD model is the first and one of the most crucial steps in the CNC milling process. This digital representation serves as the blueprint for the physical component to be machined. Here’s a detailed look at the significance of a CAD model, considerations for designing a machinable part, and the importance of precision.

Creation and Significance of a CAD Model

A CAD (Computer-Aided Design) model is a detailed 2D or 3D representation of the part to be machined. Engineers and designers use CAD software to create these models, which include all the necessary dimensions, geometries, and specifications. The significance of a CAD model lies in its ability to:

- Visualize the Design: Provides a clear and precise visualization of the part before production begins.

- Communicate Specifications: Acts as a comprehensive guide for CNC milling manufacturers, ensuring all design details are communicated accurately.

- Facilitate Modifications: Allows easy adjustments and optimizations to the design before machining, saving time and resources.

Considerations for Designing a Machinable Part

When designing a part for CNC milling, several considerations must be taken into account to ensure the part is machinable:

- Material Selection: Choose materials compatible with CNC milling, such as metals (aluminum, steel, titanium) or plastics (ABS, polycarbonate, nylon).

- Tool Accessibility: Ensure that all features of the part can be accessed by the cutting tools. Avoid designs that require tool paths that are difficult to reach.

- Tolerance and Fit: Define acceptable tolerances and fits to ensure parts can be assembled and function correctly.

- Complexity and Feasibility: Balance design complexity with manufacturing feasibility. Highly intricate designs may require advanced milling techniques or multiple setups.

Importance of Precision in the CAD Model

Precision in the CAD model is vital for successful CNC milling. Accurate dimensions and detailed specifications ensure that the final machined part meets all design requirements.

Precision in the CAD model helps to:

- Achieve Exact Specifications: Ensures the final product adheres to the specified dimensions and tolerances.

- Minimize Errors: Reduces the risk of errors during the machining process, leading to higher quality and fewer defects.

- Optimize Production: Facilitates efficient tool paths and machining strategies, optimizing production time and material usage.

Converting CAD to CNC

The process of converting a CAD model into a CNC program involves several critical steps, primarily facilitated by CAM (Computer-Aided Manufacturing) software. This process ensures that the digital design is accurately translated into machine instructions that the CNC milling machine can execute.

Converting a CAD Model into a CNC Program

The CAD model, created in CAD software, is imported into CAM software. The CAM software analyzes the model and generates toolpaths, which are the precise movements and operations the CNC machine will perform. This includes defining cutting sequences, tool changes, and speeds and feeds.

Role of CAM Software

CAM software plays a pivotal role in this step by:

- Generating Toolpaths: Converts the CAD model into detailed instructions for the CNC machine.

- Simulating Machining Operations: Allows for the visualization of the machining process, ensuring that the toolpaths are optimized and free of errors.

- Producing G-Code: The CAM software converts the toolpaths into G-Code, the language used by CNC machines to control tool movements and operations.

Importance of Simulating the CNC Program

- Identifying Errors: Detects potential issues in the toolpaths, such as collisions or inefficiencies.

- Optimizing Performance: Ensures the machining operations are as efficient and effective as possible.

- Preventing Material Waste: Reduces the risk of errors that could lead to wasted materials and time

What Are the Benefits of CNC Milling?

CNC milling offers several advantages over traditional machining methods, making it the preferred choice for many manufacturers. Here are the key benefits:

Enhanced Precision and Accuracy

CNC milling machines, controlled by computers, ensure high precision and accuracy. They can follow detailed CAD models, achieving tight tolerances and producing consistent, identical parts, even with complex geometries.

Increased Efficiency and Productivity

Operating at high speeds, CNC milling machines can run continuously, boosting productivity. Automated tool changes and advanced programming reduce downtime, making production faster and more efficient.

Greater Flexibility

CNC milling machines are easily reprogrammable for different tasks, allowing quick transitions between parts and designs. They can machine a wide range of materials, from metals to plastics, catering to diverse industry needs.

Cost-Effectiveness

Despite the high initial investment, CNC milling offers long-term cost savings. Precision machining reduces material waste, while automation lowers labor costs by minimizing the need for skilled labor.

What Are the Benefits of CNC Milling?

CNC milling achieves high precision and tight tolerances through computer-controlled operations, which precisely follow detailed CAD models and G-Code instructions. The ability to control tool movements down to microns ensures that each part is manufactured exactly to specifications, resulting in exceptional accuracy.\

The impact of precision on product quality is significant. High precision ensures that each component fits perfectly within assemblies, functions as intended, and has a superior finish. This precision reduces the need for post-machining adjustments and minimizes defects, leading to higher quality products and increased customer satisfaction.

CNC Milling Allows for High Production Output

CNC milling is highly efficient and capable of high-speed operations, making it ideal for large-scale production. These machines can run continuously, 24/7, with minimal downtime for maintenance or tool changes. Automated tool changers and advanced programming capabilities ensure that production is fast and efficient.

The ability to maintain high production output with consistent quality makes CNC milling a preferred choice for manufacturers needing to meet large order volumes quickly without compromising on precision.

CNC Milling is a Less Labor-Intensive Process

CNC milling is highly automated, reducing the need for manual intervention. The automation of CNC milling processes means that once a machine is set up and programmed, it can run with minimal supervision. This reduces labor requirements, leading to significant cost savings.

Fewer manual operations also reduce the likelihood of human error, enhancing the overall accuracy and reliability of the machining process. This automation allows skilled operators to oversee multiple machines simultaneously, further increasing productivity and efficiency.

CNC Milling Machines Ensure Uniformity

CNC milling machines are known for their consistency and repeatability. Each part produced is identical to the previous one, ensuring uniformity across production runs. This consistency is crucial for maintaining high standards in manufacturing processes, especially in industries where precision is critical.

How Much Does CNC Milling Cost?

The cost of CNC milling varies widely based on several factors, including the type of machine used, the material, and the complexity of the part being machined. Understanding these factors can help you estimate the potential costs for your CNC milling projects.

Factors Influencing CNC Milling Costs

- Machine Type: Different CNC milling machines have varying capabilities and costs. High-end, multi-axis machines typically cost more to operate but can handle more complex parts with greater precision and efficiency.

- Material: The type of material used significantly impacts the cost. Metals like titanium and stainless steel are more expensive than aluminum or plastics due to their hardness and machinability.

- Complexity of the Part: Parts with intricate designs, tight tolerances, and complex geometries require more time and advanced machining techniques, increasing the overall cost.

- Production Volume: Larger production runs can reduce the per-part cost due to economies of scale. Setup costs are spread over a greater number of parts, making high-volume production more cost-effective.

- Setup and Programming: Initial setup and programming time add to the cost, especially for custom or one-off parts. Once the machine is set up, producing additional parts becomes more cost-efficient.

- Tooling and Maintenance: Specialized tooling and regular maintenance of CNC machines add to operational costs. High-precision tools and frequent tool changes for complex parts also influence the overall cost.

Potential Cost Savings from High Efficiency and Reduced Waste

- High Efficiency: CNC milling machines operate at high speeds and with great precision, reducing production time and labor costs. Automated processes and advanced programming capabilities also contribute to cost efficiency.

- Reduced Waste: Precision machining minimizes material waste, lowering the cost of raw materials. Accurate toolpaths and optimized machining strategies ensure that only the necessary material is removed, further enhancing cost savings.

- Economies of Scale: For larger production runs, the initial setup and programming costs are distributed over a greater number of parts, reducing the per-part cost. This efficiency makes CNC milling cost-effective for high-volume manufacturing.

What Are the Available CNC Milling Services?

At Mia Makina Demir Çelik San. ve Tic. Ltd. Şti., we offer a comprehensive range of CNC milling services designed to meet the diverse needs of our clients across various industries. Our advanced facilities and expert team ensure that we deliver high-quality, precise, and efficient machining solutions. Here’s an overview of the CNC milling services available at Mia Makina:

Prototype Milling

We specialize in creating high-precision prototypes that help our clients validate their designs before moving into full-scale production. Our prototype milling services ensure that you receive accurate, functional prototypes that meet your specifications and design requirements.

Small Batch Production

For clients needing limited quantities, our small batch production service offers the perfect solution. We provide high-quality parts with quick turnaround times, ensuring flexibility and cost-efficiency for projects that do not require mass production.

High-Volume Production

Mia Makina is equipped to handle large-scale manufacturing projects. Our high-volume production services ensure consistent quality and precision across thousands of parts, making us a reliable partner for industries requiring mass production capabilities.

Custom Part Manufacturing

We cater to custom part manufacturing needs, delivering bespoke components tailored to your exact specifications. Whether it’s a unique design or a complex geometry, our CNC milling services can produce high-quality custom parts efficiently and accurately.

Multi-Axis Milling

Our state-of-the-art CNC machines include multi-axis capabilities, allowing us to perform complex milling operations that require movement along multiple axes. This service is ideal for parts with intricate designs and tight tolerances.

Precision Machining

Precision is at the core of our CNC milling services. We utilize advanced technology and meticulous processes to ensure that every part meets stringent quality standards, achieving tight tolerances and exceptional surface finishes.

Rapid Milling

For projects with tight deadlines, our rapid milling services offer expedited production without compromising on quality. We streamline our processes to deliver quick turnaround times, ensuring you receive your parts when you need them.

Milling for Various Materials

We have expertise in milling a wide range of materials, including:

- Metals: Aluminum, steel, titanium, brass, and more.

- Plastics: ABS, polycarbonate, nylon, and other engineering plastics.

- Composites: Advanced composite materials used in aerospace and automotive industries.

Secondary Operations

In addition to primary milling services, we offer a variety of secondary operations to complete your parts. These include:

- Deburring and Finishing: Ensuring smooth edges and surfaces.

- Surface Treatments: Coatings and treatments to enhance durability and aesthetics.

- Assembly: Providing assembly services for multi-component parts.

By offering a wide range of CNC milling services, Mia Makina ensures that we can meet the diverse needs of our clients, from prototype development to high-volume production. Our commitment to quality, precision, and customer satisfaction makes us a leading CNC milling manufacturer and supplier in the industry.