What is Flange? Flange Types and Usage Areas

Flange is an important technical connection element, especially used in the connection of pipelines, valves and various equipment. Flanges, which are generally made of metal, are of great importance in production and industrial processes. In this article, we will provide detailed information on topics such as what is flange, flange types, usage areas and how flange dimensions are determined.

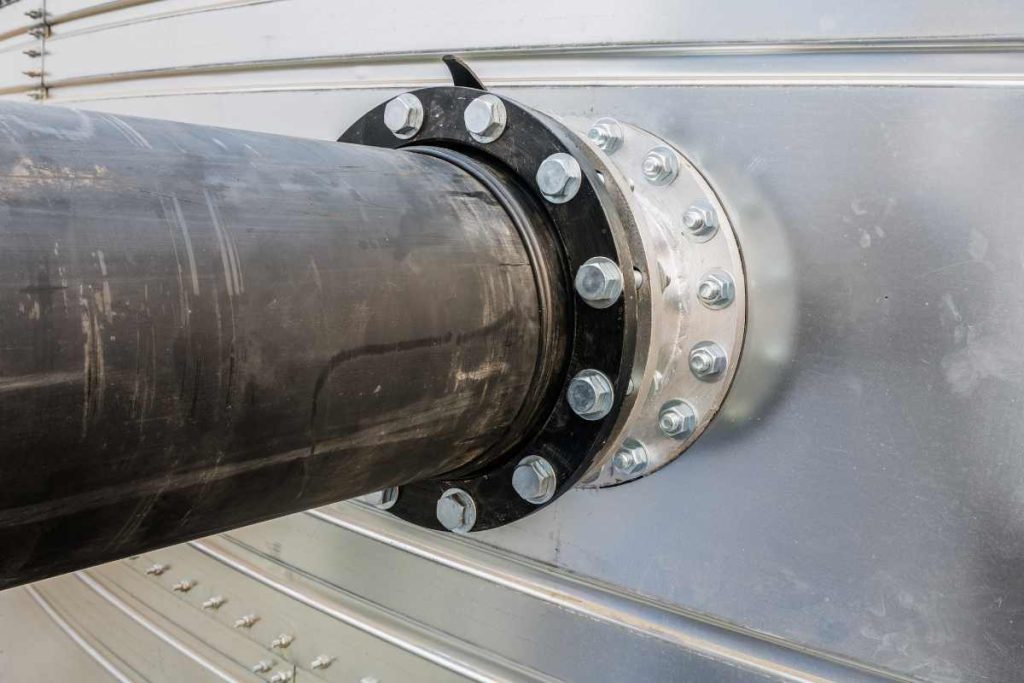

What is Flange?

Flange is an element that provides a secure connection by joining the ends of pipes, valves and other equipment. Flanges are widely preferred because they facilitate assembly and disassembly. They are used in all kinds of piping systems that need sealing and robustness at the connection points.

Especially in industrial processes under high pressure and temperature, flanges are preferred to increase the reliability of the systems. Flanges, as pipe fittings, allow the system to operate more flexibly and safely.

Where is Flange Used?

Flanges have a wide range of applications and are particularly used in industrial plants, piping systems and critical processes such as power generation.

Industrial Areas

Flanges are widely used in industrial areas such as chemical plants, power plants, oil and natural gas lines. Safe and efficient operation of piping systems depends on the correct use of these fittings.

In chemical and petrochemical plants, flanges are used to ensure a reliable connection under high temperature and pressure conditions. In addition, the use of flanges is of vital importance in piping systems where pressurised water vapour is transported in power plants.

Water Treatment and Transmission Systems

Flanges are also frequently used in water treatment plants and pipelines where water must be transported. In such systems, flanges offer great convenience in maintenance operations as they provide the advantage of easy assembly and disassembly. Especially in the installation of large diameter pipelines, such fittings are important both in terms of reliability and practicality.

High Pressure Systems

Piping systems used in the oil and gas industry must be resistant to high pressure. Flanges are used to provide sealing and secure connection in such systems. In addition, when pipelines need to be checked periodically, these operations can be done easily thanks to flanges.

What Does Flange Do?

The main function of flanges is to provide a safe and durable connection of pipe systems. Flanges help the systems to work efficiently by sealing the connection points. Flanges offer great convenience when pipelines need to be disassembled and reassembled.

This is especially important in systems that require frequent maintenance and repair. In addition, the sealing level of flanges can be increased by using gaskets. Thanks to these features, flanges provide energy efficiency and increase the reliability of systems.

Flanges are also used when pipelines need to be extended, equipment needs to be connected and a certain part of the system needs to be isolated. This flexibility makes flanges indispensable in industrial plants.

What are Flange Types?

Flanges are produced in various types according to different purposes and application areas. Below we will examine the commonly used flange types and their properties.

- Blind Flange (Blind)

Blind flanges are used to close the ends of piping systems. Such flanges are preferred for the purpose of stopping any flow in the system and isolating a certain part of the pipeline. Blind flanges are used to provide isolation, especially during maintenance and repair work of certain parts of the system.

- Welding Neck Flange

Weld neck flanges are flanges that are welded to pipelines and provide a durable connection under high pressure and temperature. Thanks to the welded manufacturing, these flanges create secure and leak-proof connections. This type of flange offers a long-lasting connection and is generally preferred in petrochemical plants, power plants and high-pressure systems. The correct installation of weld neck flanges is critical for the safe operation of the pipeline.

- Flat Flange

Flat flanges are generally used in low pressure systems and to provide connections on flat surfaces. These flanges are easy to install and ensure a smooth connection of the pipes. Flat flanges offer an economical solution for low pressure water and gas pipes and are therefore used in many industrial plants.

- Threaded Flange

Threaded flanges allow installation with threaded pipes and are often used in applications that do not require gas welding. Threaded flanges are particularly useful in temporary pipework systems or low pressure applications. Easy assembly and disassembly makes these flanges ideal for systems requiring maintenance.

- Socket Weld Flange

Welding socket flanges are used in small diameter pipelines and are welded by inserting them into the pipe. This ensures a strong and leak-proof connection. This type of flange plays an important role in securely connecting small diameter pipelines and offers a suitable solution for high pressure systems.

- Slip-On Flange

Slip-On flanges are assembled by welding the pipe through the flange and are generally used in low pressure systems. They are easy to install and offer a low cost solution. Slip-On flanges are preferred during the installation of large diameter pipe systems and provide advantages in terms of cost effectiveness.

How to Determine Flange Dimensions?

Factors such as diameter, thickness, pressure class and material type are taken into consideration when determining the dimensions of flanges. The production of flanges in accordance with international standards (ISO, ANSI, DIN, etc.) is of great importance for the safety and efficiency of the systems.

Determining the dimensions correctly prevents problems that may occur during assembly and ensures that the connection is leak-proof. When determining flange dimensions, the pressure class and ambient conditions to be used should also be taken into consideration.

In addition, laser cutting techniques ensure that the flanges are produced in the correct dimensions and that there are no problems during assembly. Especially in systems under high pressure and temperature, the durability of flanges is very important.

Flanges are important connection elements that ensure safe, durable and flexible connection of pipelines in industrial and production processes. Flanges designed in accordance with high pressure, temperature and various industrial conditions make it possible for systems to operate efficiently and reliably.

Mia Makina offers high quality and durable flange solutions to industrial organisations. Using modern production techniques such as CNC machining, laser and plasma cutting, it ensures that flanges are produced in precise dimensions. If you need reliable and high quality flange solutions for your projects, you can add value to your production processes by contacting us.