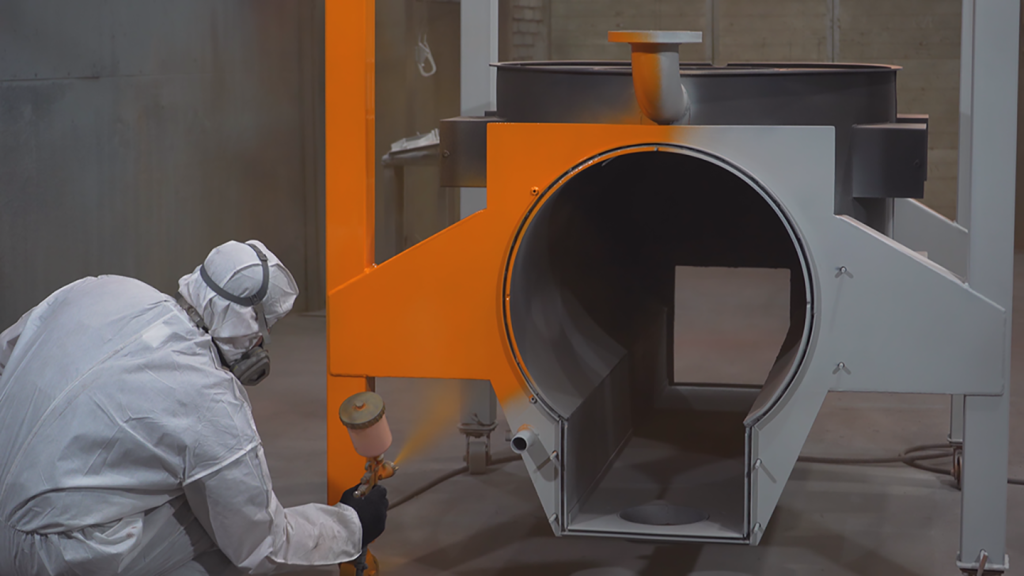

PAINTING PROCESS

The painting process is applied to protect metal surfaces from environmental impacts, make them resistant to wear, and give them an aesthetic appearance. Various painting and coating techniques are used to protect against corrosion, moisture, chemicals, and mechanical impacts.

The painting process has been developed to meet the material and sector requirements, ensuring the creation of long-lasting and highly durable surfaces.

Types of PaIntIng and Areas of Use

- Electrostatic Powder CoatingTypes of Painting and Areas of Use: Electrostatic Powder Coating This is an environmentally friendly method that does not contain solvents and creates smooth, durable coatings. It is used for industrial machines, automotive parts, and metal furniture.

- Industrial Liquid PaintingPreferred for large-scale metal structures and industrial equipment. It is widely used in the maritime, aviation, and heavy industry sectors and is resistant to chemicals and high temperatures.

- Painting Over Galvanized SurfacesThis is a special painting process applied over galvanized coatings. It provides protection against corrosion for steel structures in the construction sector.

- Special Coatings for Aluminum and Stainless SteelAnodizing and colored coatings can be applied to aluminum surfaces, and transparent or colored coatings are used for stainless steel surfaces.

Sector-Specıfıc Productıon Solutıons:

- Construction Sector:Steel structural elements used in construction projects must be long-lasting and durable. High-strength special paint and coating solutions are applied to extend the lifespan of steel columns and beams, and enhance the safety of structures.

- Automotive Sector:In the automotive industry, both aesthetics and durability are crucial. Special paints used on engine components, chassis elements, and body panels provide extra protection against high temperatures, friction, and chemicals. Electrostatic powder coating applications give automotive parts superior resistance to impacts and scratches, ensuring long-term use and a high-quality appearance. Additionally, surface treatment solutions are applied to prevent rust on vehicle metal components, enhancing performance and safety.

- Heavy Industry and Machinery Sector:Heavy industrial machinery is exposed to high temperatures, excessive loads, and harsh working conditions, making surface treatments crucial. Special heat and wear-resistant paint coatings are applied to large-scale industrial machines, ensuring the components work efficiently for longer.

- Maritime and Shipbuilding SectorIn the maritime industry, metal surfaces are constantly exposed to saltwater, moisture, and abrasive environmental factors, requiring extra protection. Special anti-corrosive paints and coatings are applied to ship hulls and marine vehicles, preventing corrosion caused by seawater.

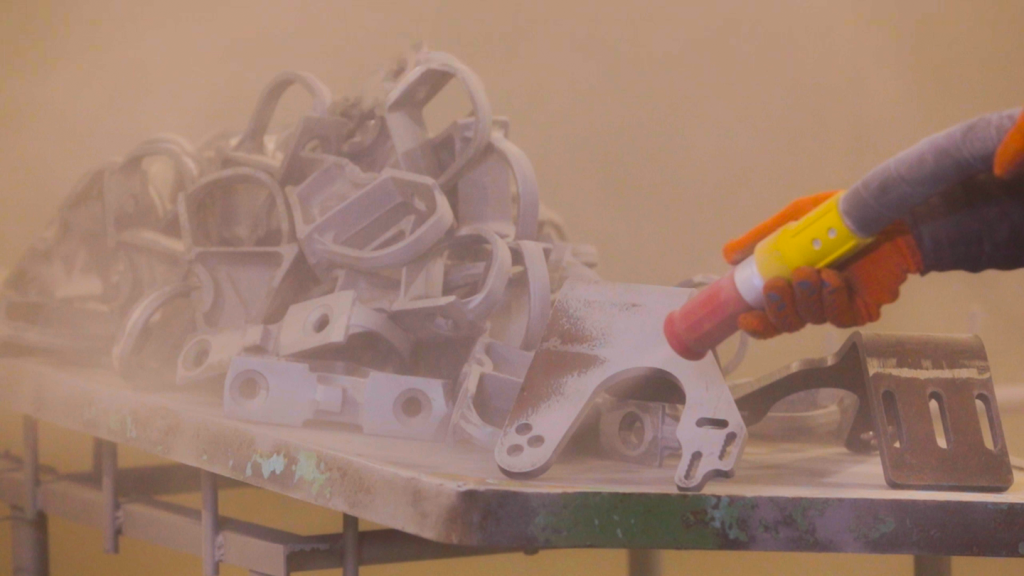

SANDBLASTING PROCESS

Sandblasting is a mechanical surface cleaning method used to remove rust, oxide layers, oil, dirt, and old paint residues from metal surfaces. This process ensures that surfaces are properly prepared for painting and other coating operations.

During sandblasting, abrasive materials are sprayed at high speeds to create a rough texture on the surface. This helps coatings adhere better to the surface, increasing their lifespan.

Types of SandblastIng and Areas of Use:

- Sandblasting with Steel BallsUsed for cleaning high-strength industrial equipment and heavy steel constructions, ensuring homogeneous distribution of coatings.

- Grit Blasting with Sharp AbrasivesEffective on rusty and corroded surfaces, it ensures that paint and coatings adhere well to the surface. Ideal for cleaning large metal structures such as steel bridges, pipes, and ship hulls.

- Glass Bead BlastingUsed for cleaning delicate surfaces without damaging them, creating a matte decorative finish. Preferred for materials such as stainless steel and aluminum.

- SandblastingUsed to clean heavy dirt, rust, and old coatings from metal surfaces. Frequently applied for surface preparation before painting and widely used in the construction sector for steel columns.

Sector-Specıfıc Productıon Solutıons:

- Construction Sector:Steel columns, beams, and other large metal structures are cleaned of rust and dirt to prepare them for coating operations. Sandblasting ensures surface preparation to protect these structures from corrosion.

- Automotive SectorVehicle components and engine parts are cleaned using sandblasting, ensuring smooth and uniform surfaces for paint applications. This helps in creating long-lasting and durable coatings.

- Machine IndustryHeavy machines and industrial equipment are cleaned of dirt, rust, and old coatings using sandblasting, increasing the efficiency of machines while preparing them for coating processes.

- Maritime and Shipbuilding SectorThe hulls of ships and marine vehicles are cleaned with sandblasting to prepare for saltwater-resistant coatings. This process helps ships remain durable underwater for long periods.